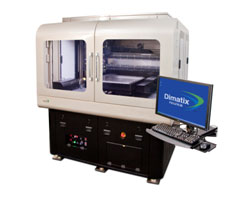

FUJIFILM Dimatix Launches New DMP-5005 Materials Printer

07/2011

FRANKFURT, Germany – FUJIFILM Dimatix introduced the DMP-5005 complementing its extensive line of Materials Printers. The DMP-5005 is a large format, non-contact, fluid deposition system capable of jetting a wide range of fluid types using the Fujifilm Dimatix 16-jet, 1 or 10 picoliter user-fillable cartridges for product and process development and up to five sequentially operating 128-jet, 1 or 10 picoliter print heads with up to five different functional fluids.

The new DMP-5005, like the earlier introduced DMP-5000, has a printable area of 500 by 500 mm and maintains a positional accuracy and repeatability of ± 5 microns and ± 1 microns, respectively. The printer uses a temperature controlled vacuum platen to accurately register, maintain and thermally manage substrates during printing. These substrates include plastic, glass, ceramics, and silicon, as well as flexible substrates ranging from membranes, gels, and thin films to paper products.

An integrated drop visualization system captures droplet formation images dynamically as droplet ejection parameters are adjusted to produce a tuned print head and fluid combination. Also, sophisticated electronics allow each print head to be calibrated on a per nozzle basis to provide the ultimate in printing accuracy. A second camera system allows precise pattern printing location feature measurement and observations of fluid drying behavior.

The Dimatix Materials Cartridge is a 16-jet, user-fillable, snap-in replaceable print head and fluid supply used with all DMP models and is available in 1 picoliter and 10 picoliter drop volumes. The industry-first 1 picoliter cartridge can deposit features as small as 20 microns (20 millionths of a meter) and below to fabricate products such as organic thin-film transistors (TFTs) and printed circuits.

D-Class print heads have 128 individually addressable jets and are constructed using silicon MEMS technology similar to the Dimatix Materials Cartridge, thus enabling direct translation of findings from one print head to the other. With the industry's only 1 picoliter production piezoelectric print head, the D-128 DPN Print heads are also the only print heads with integrated cooling capability to maintain fluid viscosity for operation over heated substrates. The D-128 DPN 1 picoliter and 10 picoliter print heads share identical physical features for easy interchangeability. Both are further enhanced using driver-per-nozzle capability, which allows the ultimate in print head tuning between each of the 128-jets. This trimming feature ensures drop volume uniformity, essential for dispensing applications or modifications to drop velocity for increased placement accuracy, critical for patterning applications especially when using very small drop sizes.

——<Recharger Magazine>

All brand names and trademarks are the properties of their respective owners and are referred to here for descriptive purposes only.

All brand names and trademarks are the properties of their respective owners and are referred to here for descriptive purposes only.